Print this page

Revised June 14, 2006

Revised of 8/10/2016

Reviewed 2/1/2017

Purpose and Intent

- A fire officer undertakes the responsibility of protecting lives and property in their community. It is the intent of the Tender Task Force (TTF) Guidelines to make the job as easy as possible.

- When the TTF is requested, their job is to deliver a minimum of 1000 gallons per minute (GPM) of water in the quickest and safest way possible by obeying all motor vehicle laws. It is very important that all apparatus in the operation be able to adapt with each other

Scope

- This guideline applies to all emergency agencies operating within Burlington County that have a need to request a water tender task force or strike team.

- It is the intent of this guideline to ensure compliance with the National Incident Management System (NIMS). Standard terminology, strike team components, and other resources are identified using NIMS guidelines.

Standard Operating Guidelines

- When an Incident Commander arrives on or is confronted with a fast moving fire and they feel that their local response or water system will not be sufficient, a call to Central Communications will activate the first alarm from the TTF.

- When the TTF is dispatched, it will respond with two qualified Water Supply Group Supervisors (WSG). Once the qualified WSG's arrives he/she will be appointed by Command as the WSG. He/she shall be identified by wearing a vest stating “Water Supply”. The second qualified WSG will be the Portable Pond Unit Leader (PPL). He/she will be identified by wearing a reflective vest stating “Portable Pond”.

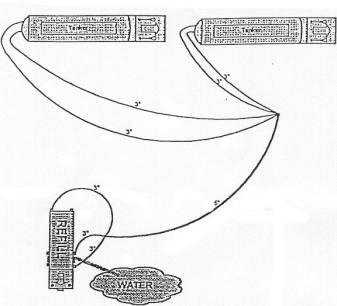

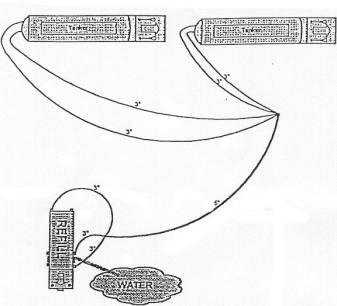

- The WSG must decide where the portable pond operation will be set up in relationship to the fire grounds. The water supply point is the unloading point for the Tenders and the point at which water is supplied to the fire grounds. This point must get set up away from the fire grounds where equipment, including the tenders, can flow freely in and out of the fire scene.

- The object of establishing a Water Supply Point is to better utilize and control all incoming tenders and still allow maximum water flow.

- It may be necessary to move some tenders to the fire grounds to supply the scene while the operation is being set up. This way the fire ground does not run out of water. Once the operation is set up and water is flowing to the fire ground, the tender(s) that was supplying the scene can break down and enter the water shuttle.

- The flow required on the fire ground will be determined by the size of hose that was laid into the scene. This will determine how the WSG has to set up the operation.

Procedure

- The following basic procedures are common to all TTF operations and should be understood and practiced.

- Tenders:

- When a full-scale operation is not needed, a supply tender can be used to supply the fire scene. Incoming tenders can unload their water through supply lines from the supply tender. This tender will have a pump size no smaller then 750 GPM.

- When a full-scale operation is needed, the first due tender with a portable pond should drop off the pond and all loose equipment (see Sect.8) and help set up the pond. It also might be necessary for the second and third tender to do the same. The WSG will determine where the ponds will be set up. Once the ponds are set up, tenders can start unloading by using their dump valves which should be 8” or larger.

- After unloading in the pond, the tender will then proceed to the designated refill point(s). When the shuttle loop has multiple refill points, the following system should be utilized:

- Empty tenders should always stop at the first refill point unless waved around.

- Tender drivers should stop if they can be loaded immediately by one of the two sets of refill lines or if their tender is the first in line behind the two filling tenders.

- If these conditions do not exist, the tenders should move on to refill point two.

- Nurse Tenders:

- A nurse tender can be used two different ways. The nurse tender can be setup away from the portable ponds to supply the pond operation when the ponds become low. The nurse tender can also be setup between the ponds and the fire grounds and be used to supply the fire grounds directly while being filled by the pond.

- Refill Points

- It is extremely important that refill points be established immediately. Command should give these points. If the WSG knows the area, he/she should pick the closest refill point to the area. Ideally, refill points should be set up on the same traffic routes.

- When setting up refill points, the first one in the loop will be called Refill Point One and the next one Refill Point Two.

- Refill Engine:

- The refill engine will have at least a 1250 gpm pump.

- The engine is required to have at least 20’ of hard suction. Enough sections should be used to allow for dropping water levels over the length of the operation.

- Required to have at least 400’ of either 3” or 2 1/2” or a combination of each and barrel strainer or a floating dock.

- Two lines will be stretched to the front of the engine and two to the rear.

- Once the water supply has been established the WSG shall be notified.

- When refilling has started, the crew of the engine will make all connections to the tenders. The tender driver and/or officer shall remain in the Tender.

- Only one tender will be filled at a time. The second may be hooked up and be ready to be filled as soon as the other tender is filled.

- Refill Engine With A Manifold

- In some cases it might be necessary for the refill point to be off the roadway or a distance from the loop.

- Drop the manifold with 300’ of 3” or 2 ½” hose. Hook up two 50’ sections and two 100’ sections to four different discharges of the manifold. Leave a crewmember with the manifold with a portable radio.

- Lay a LDH line from the manifold into the draft point. Supply the manifold by connecting directly to a LDH discharge or by using a clapper valve.

- Once the refill engine establishes a water supply, that engine will communicate with the crewmember at the manifold to send the water and bleed off the air from the LDH.

- Pond Operations

- Supply Engine

- The supply engine will have at least a 1250 gpm pump and carry a low level strainer (pond sucker). This engine will draft out of the main supply pond using the side suction. When a large amount of water is needed, both front and side suctions will be used.

- When connecting to the supply line, a clapper valve (3 to 1) must be used to connect to the supply line that was laid to the scene.

- Transfer Engine

- The transfer engine will have a least a 1000 gpm pump.

- This engine will draft from the main pond while moving water from the transfer ponds to the main pond. This will be done using a jet transfer fitting connected to a section of hard suction and two 1 ½” or 1 ¾” hand lines.

- The hard suctions are placed between the transfer pond (s) and the supply pond with the jet transfer fitting in the transfer pond (s). The hard suctions will be tied down to eliminate fluctuations in the hose.

- When a tender is unloading, this is the pond that you will be transferring water out of to the supply pond. This will help eliminate a tender backup at the pond operation

- Staging:

- There should be at least two engine companies in staging during the operations. These engines could be used to replace an engine that might breakdown, supply a nurse tender, operate in the shuttle, etc.

Responsibilities

- Water Supply Group Supervisor (WSG):

- Determine if a full-scale operation is needed or if a supply tender can handle the operation

- Placement of the equipment

- Additional equipment needed to supplement the tender operation

- Establish refill points

- Determine need for fire police

- Portable Pond Unit Leader (PPL):

- Assist WSG in setting up his/her operation

- Set up safety cones

- Assign Tender spotter

- Monitor Tender unloading

- Maintain record of total gallons unloaded

- Keeps communication with the WSG

- Refill Unit Leader:

- Establish control and monitor refill operations

- Request additional equipment

- Monitors flow of empty tenders so there is no backlog at their point

- Keeps communication with the WSG

- Staging Area Manager:

- In charge of all apparatus in Level II staging.

- Position apparatus so that any unit can immediately be released to its assignment.

- Drivers:

- Must know and understand the operating principles and procedures of this guideline.

- Must operate their apparatus in a safe manner by obeying all speed limits.

- Monitor radio for instructions.

- When in staging, listen to the Staging Area Manager for assignments.

Dispatching Guidelines

- Apparatus will be dispatched using the term TTF Assignment.

- Apparatus on the first alarm will be dispatched to the fire ground unless otherwise indicated by the IC.

- Cover assignments will be dispatched automatically unless an officer requests that his/her station not be covered.

- The Burlington County Fire Coordinator shall be notified on the first alarm of the TTF.

- The Burlington County Fire Police shall be dispatched on the Second Alarm.

Radio Guidelines

- Radio traffic must be kept to an absolute minimum. If directions are needed, this should be done via telephone prior to leaving the station.

- Apparatus responding to the fire grounds, staging area, or cover assignment will switch their radios to a designated channel as directed by Central Communications.

Personal Safety Guideline

- Personal safety of the firefighters at a TTF operation is of primary importance.

- Firefighters are required to bring approved personal protection equipment during a TTF Operation.

- Each apparatus responding should have a crew size no more than equal to the seating capability.

- Each officer and firefighter responding must use an approved accountability procedure.

- If an apparatus must leave the incident for any reason, a head count must be taken.

- Apparatus will be responding from all parts of Burlington and other Counties. Chiefs and apparatus operators must consider their apparatus is traveling in an area that is out of their normal coverage area. Different and unfamiliar roads and confused motorists increase our exposure for a problem. Every apparatus operator must use extreme caution during his/her response. Responding and arriving safely with your crew is very important.

- All firefighters committed to an operation must stay within that particular operation.

Apparatus Guidelines

- Apparatus needed for a TTF Operation are:

- Tenders with at least 2500 gallons of water.

- Engines with l250 gpm pumps or greater to be able to draft, supply or refill.

- Nurse Tenders

- Transfer Engines with at least 1000 gpm pumps.

- The unit ID. number will be placed on the front bumper.

- Apparatus should have a minimal restriction on maneuverability.

Equipment

- The following equipment is recommended for this operation:

- Tenders:

- 4 1/2" NST hydrant adaptor.

- Rear Dump with an 8" minimum discharge.

- Side Dumps (suggested)

- Portable Pond (minimum of 3000 gal.).

- Number signs for portable ponds ex. 1, 2, and 3.

- Vests with WATER SUPPLY and Portable Pond Unit Leader.

- 6" Low Level Strainer

- Jet Transfer Fitting (s)

- Wheel Chocks

- Safety Cones

- Engines:

- Adaptors to 4 1/2", 5", and 6".

- 400’ of 2 ½” or 3"hose.

- Hard Suction 20' minimum (30' Suggested)

- Barrel Strainer or Floating Dock

- Manifold w/4 discharges (if carried)

- Wheel Chocks

- Safety Cones

- Companies dropping ponds should place all loose equipment next to their pond.

- All equipment should have the company's name or identifying number on it.

Terminology Guidelines

- Portable Pond(s): Are portable reservoirs, (of at least 3000 gal.) and are used when a full-scale operation is needed. Incoming tenders unload their water through dump valves. This water is then sent to the fire ground by either a supply engine or to a nurse tender then sent to the fire ground.

- Portable Pond Unit Leader: Assists the Water Supply Group Supervisor in setting up the operation. He/she also sets up safety cones, assigns tender spotters, monitors the tender unloading, and maintains records of the total gallons unloaded.

- Refill Engine: Is an engine with at least a 1250 gpm pump to draft or hookup to a water supply to fill tenders.

- Refill Point: Is the location where tenders are sent when they are empty to refill. This water supply can be from drafting out of lakes, streams, ponds, dry hydrants, municipal hydrants, or basically from any water source available.

- Staging Area Manager: Monitors the staging areas and keeps a list of equipment that is in staging. He/she also positions apparatus so they can move in and out freely.

- Supply Engine: Is an engine of at least 1250 gpm to draft out of the portable ponds to supply the fire grounds.

- Supply Pond: This is the main portable pond that a supply engine drafts from to supply the fire grounds.

- Supply Tender: Is a tender with a pump size no smaller then 750 gpm. This tender is used when a full-scale operation is not needed. Incoming tenders unload their water through discharge lines that hook--up directly to the supply tenders rear intakes.

- Tender: Is an apparatus capable of holding at least 2500 gallons of water.

- Transfer Engine: Is an engine of 1000 gpm or more to transfer water from the transfer pond(s) to the supply pond.

- Transfer Pond: Are ponds where tenders unload their water. These ponds provide water for the supply pond.

- Water Supply Group Supervisor (WSG): Is in charge of all water supplied to the fire grounds. He/she determines if additional equipment is needed. Also establishes refill points.

Closing

- All fire departments in Burlington County shall receive a copy of this plan. All Chief Officers shall become familiar with this plan.

- Any plan previously published that is in conflict with this plan is hereby rescinded.